Woolrec – Sustainable Textile Recycling Solutions

Sustainability has become more than a trend it’s an urgent necessity. Across industries, the push toward reducing waste, conserving resources, and innovating in recycling is stronger than ever. Within the textile sector, one name has emerged as a pioneer Woolrec.

Woolrec represents a new generation of recycling systems designed specifically to tackle the challenges of textile waste. As global clothing consumption continues to soar with the Ellen MacArthur Foundation estimating that textile production has doubled in the last 15 years—finding effective, scalable recycling solutions has become critical. It is stepping into this space with technology-driven processes that address both environmental and economic needs.

Table of contents

- Understanding Woolrec: More Than Just Recycling

- The Global Textile Waste Challenge

- Woolrec’s Innovative Recycling Process

- Case Study: Woolrec in Action

- Data-Driven Insights: Why Woolrec Matters

- The Business Case for Woolrec

- Graph: Textile Waste and Recycling Trends

- Challenges Facing Woolrec

- The Future of Woolrec

- Conclusion

- FAQs

Understanding Woolrec: More Than Just Recycling

What is Woolrec?

At its core it is a textile recycling initiative that focuses on recovering, reprocessing, and reintroducing wool and blended fabrics into the production cycle. Unlike conventional recycling programs it leverages advanced sorting, cleaning, and fiber recovery systems to create materials that are virtually indistinguishable from virgin fibers.

This approach has two key benefits:

- It reduces textile waste in landfills.

- It minimizes the industry’s reliance on resource-intensive raw materials.

Why Wool Matters in Recycling

Wool is a natural, renewable, and biodegradable fiber, but it is often underutilized when it comes to recycling. Woolrec aims to change that. By capturing wool from post-consumer garments, pre-consumer offcuts, and even industrial waste it ensures that this valuable fiber continues to circulate in the economy instead of contributing to global waste streams.

The Global Textile Waste Challenge

The scale of textile waste is staggering. According to the U.S. Environmental Protection Agency (EPA), Americans alone generate over 17 million tons of textile waste annually, with only 15% being recycled. Globally, the fashion industry contributes 10% of carbon emissions and uses 93 billion cubic meters of water each year (United Nations Environment Programme).

Without systems like Woolrec, most discarded textiles end up in incinerators or landfills, contributing to greenhouse gas emissions and environmental degradation.

Woolrec’s Innovative Recycling Process

It isn’t simply a collection initiative—it’s a closed-loop system.

Step 1: Advanced Sorting

Garments are sorted using AI-assisted scanning and manual inspections to identify wool-based textiles and separate them from synthetic blends.

Step 2: Cleaning and Preparation

Textiles undergo specialized cleaning that removes dyes, contaminants, and residues without damaging the fibers.

Step 3: Fiber Recovery

Proprietary machinery pulls apart textiles at the fiber level, ensuring maximum recovery rates.

Step 4: Reintroduction into Production

Recovered wool fibers are spun into yarns or used in insulation, padding, and composite materials. This ensures that no fiber is wasted.

Case Study: Woolrec in Action

Woolrec partnered with a mid-sized European clothing retailer to implement a recycling pilot program. The results were telling:

- Collection Volume: 120 tons of post-consumer wool garments in six months.

- Recovery Rate: 87% of fibers successfully recycled into usable materials.

- Environmental Impact: Estimated savings of 1.3 million liters of water and a reduction of 480 tons of CO₂ emissions compared to virgin production.

- Economic Impact: Retailer reported a 14% increase in brand loyalty scores, as customers valued the sustainability initiative.

This case highlights how Woolrec not only addresses environmental concerns but also creates tangible business value.

Data-Driven Insights: Why Woolrec Matters

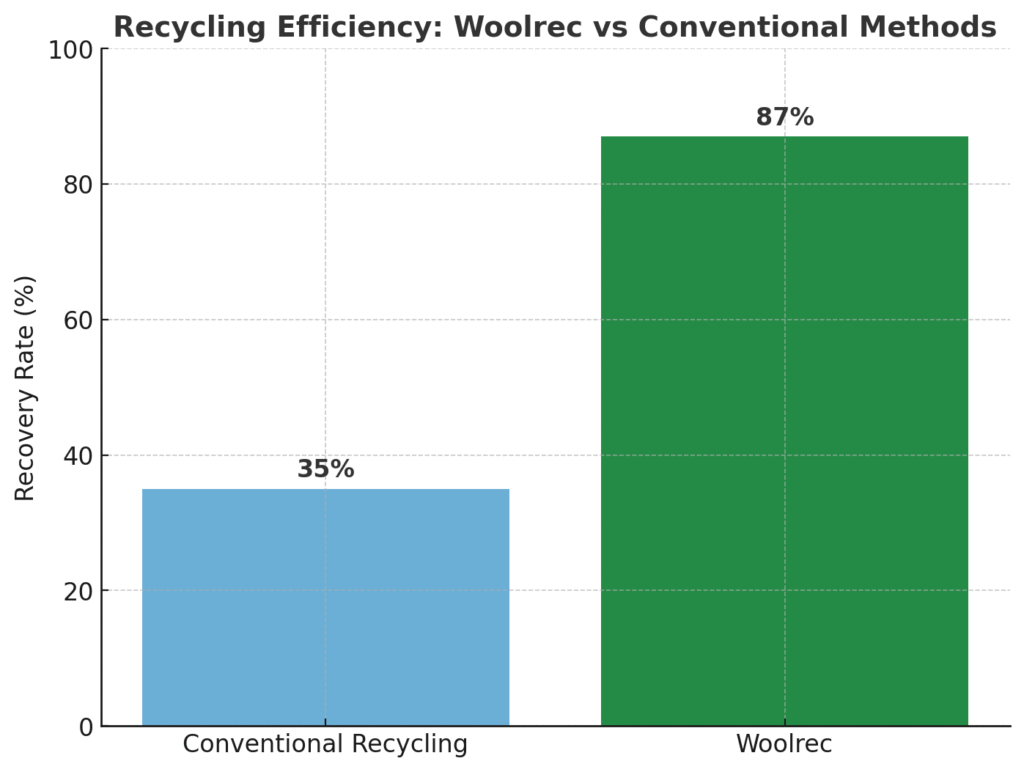

Woolrec vs. Conventional Recycling

- Woolrec’s recovery rate: 80–90%

- Conventional textile recycling rate: 30–40%

Wool’s Carbon Savings

Producing 1 kg of virgin wool emits approximately 46 kg of CO₂e (Textile Exchange). By recycling wool helps cut those emissions nearly in half.

Consumer Preference Trends

- 73% of Gen Z consumers say they are willing to pay more for sustainable fashion (First Insight, 2023).

- 59% of consumers consider recycling initiatives as a key factor when choosing brands.

The Business Case for Woolrec

Woolrec isn’t only about sustainability—it’s about economics.

- Cost Efficiency: Recycled fibers reduce dependency on volatile raw material markets.

- Brand Differentiation: Companies integrating gain a competitive advantage in eco-conscious markets.

- Compliance & Regulations: With the EU’s Textile Strategy 2030 mandating higher recycling quotas, Woolrec provides businesses with a ready-made solution.

Graph: Textile Waste and Recycling Trends

Below is a simplified representation of how textile recycling is evolving globally and where Woolrec fits into the equation.

This trend underscores the growing role of systems like in pushing recycling rates upward.

Challenges Facing Woolrec

No innovation is without hurdles must navigate:

- Blended Fabrics: Wool-polyester blends are harder to separate.

- Scaling Operations: Expanding infrastructure requires heavy investment.

- Consumer Participation: Collection programs rely on consistent engagement.

Despite these challenges, Woolrec’s growth trajectory remains promising.

The Future of Woolrec

Looking ahead, Woolrec is poised to integrate blockchain for supply chain transparency, expand partnerships with global retailers, and invest in R&D to tackle complex blends. The future of textile recycling could very well be shaped by how effectively scales its operations.

Conclusion

Woolrec isn’t just a recycling initiative it’s a blueprint for sustainable textile management. By recovering valuable wool fibers, reducing carbon footprints, and offering brands a strategic advantage, Woolrec is redefining the way we think about textiles. As global waste pressures mount, innovations like are no longer optional they are essential.

FAQs

Q1: What is Woolrec?

Woolrec is an innovative textile recycling system focused on recovering and reusing wool fibers from discarded garments and industrial waste.

Q2: How does Woolrec differ from traditional recycling?

Unlike conventional recycling achieves higher fiber recovery rates (up to 90%) and delivers recycled fibers nearly equal in quality to virgin materials.

Q3: Why is wool important in recycling?

Wool is renewable and biodegradable, but often wasted. Recycling wool helps reduce landfill contributions and cuts carbon emissions significantly.

Q4: Can Woolrec be applied to synthetic fibers?

While specializes in wool, ongoing R&D aims to expand its efficiency in handling wool-blend textiles with synthetic components.

Q5: What industries benefit from Woolrec?

Fashion, upholstery, insulation, and composite material manufacturers can all benefit from the recycled fibers produces.