Pappedeckel: Sustainable Packaging Innovation

In a world where sustainability is no longer a trend but a necessity, pappedeckel the German term for cardboard lid has emerged as a quiet revolution in the packaging industry. From coffee shops to fast-food chains and supermarkets, companies are replacing single-use plastic lids with biodegradable cardboard alternatives. What seems like a small change in packaging design is making a significant impact on global sustainability goals.

According to the European Environment Agency, packaging waste in the EU alone reached 84 million tons in 2021, with plastic accounting for nearly 20% of that figure. This makes solutions like pappedeckel not just innovative but essential for reducing environmental damage.

Table of contents

What is Pappedeckel?

At its core, a pappedeckel is a lid made from cardboard or recycled paper fibers designed to replace plastic tops for cups, bowls, and containers. Unlike traditional plastic lids, which can take centuries to decompose, pappedeckel products are biodegradable, recyclable, and often compostable.

Their lightweight yet durable structure makes them suitable for hot drinks, takeaway meals, and even larger food packaging needs. For businesses aiming to align with EU packaging directives and corporate sustainability targets, pappedeckel is becoming the go-to solution.

Market Growth of Eco-Friendly Packaging

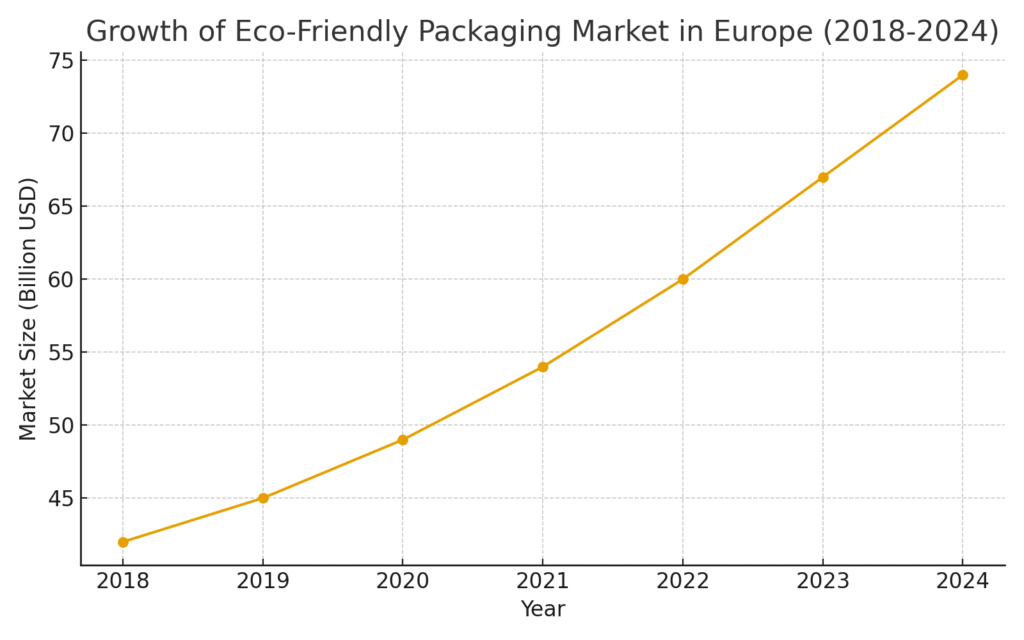

The shift toward eco-friendly solutions is not happening in isolation. The European eco-friendly packaging market has seen exponential growth, with cardboard and paper-based alternatives leading the way.

Here’s a closer look at the numbers:

Between 2018 and 2024, the European eco-friendly packaging market grew from $42 billion to $74 billion, highlighting strong demand for sustainable alternatives like pappedeckel.

Why Pappedeckel is Outperforming Plastic

1. Environmental Benefits

Unlike plastic lids that contribute to microplastic pollution, pappedeckel products are biodegradable and compostable. A study by the Fraunhofer Institute for Environmental Safety found that replacing plastic lids with cardboard could reduce carbon emissions by up to 60% across the supply chain.

2. Consumer Demand for Sustainability

Recent surveys show that 74% of European consumers prefer products with eco-friendly packaging. Coffee chains and fast-food giants adopting pappedeckel solutions are reporting higher customer satisfaction and brand loyalty.

3. Regulatory Pressure

The EU’s Single-Use Plastics Directive (SUPD) bans several plastic items, including straws and cutlery, and pushes for alternatives in food service. While lids are not yet fully banned, companies adopting pappedeckel solutions are future-proofing their business.

Case Study: Berlin Coffee Chain’s Switch to Pappedeckel

A Berlin-based coffee chain, serving nearly 1.2 million cups annually, transitioned from plastic lids to pappedeckel in 2022. Within a year:

- Plastic waste reduction: Over 12 tons annually

- Cost management: Although initial costs were 10% higher, savings came from reduced waste management fees

- Customer response: 82% of surveyed customers said they felt more positive about the brand after the switch

This case illustrates how small changes, when scaled, can bring measurable business and environmental benefits.

Challenges and Future Outlook

Despite the benefits, pappedeckel adoption faces hurdles. Production costs remain slightly higher than plastic, and durability in extreme conditions (like oily or very hot foods) can be a limitation. However, advancements in bio-coating technologies are addressing these challenges, making pappedeckel increasingly competitive.

Industry analysts project that by 2030, 40% of takeaway beverage lids in Europe will be made from cardboard, with global adoption following suit.

You Also Like this Rise of vhsgjqm:

Conclusion

The humble pappedeckel is proving that sustainability and practicality can go hand in hand. From reducing plastic waste to enhancing brand reputation, cardboard lids are reshaping the packaging industry. While challenges remain, innovation and consumer demand are pushing adoption forward at remarkable speed. Businesses that embrace pappedeckel today position themselves not only as eco-conscious but also as future-ready.

FAQs

1. What makes pappedeckel better than plastic lids?

Pappedeckel lids are biodegradable, recyclable, and produce significantly fewer carbon emissions during their lifecycle compared to plastic lids.

2. Are pappedeckel lids safe for hot beverages?

Yes. Most pappedeckel lids are designed with heat-resistant coatings that make them suitable for hot drinks like coffee and tea.

3. Do pappedeckel products cost more than plastic?

Initially, they can cost around 5–15% more. However, long-term savings come from reduced waste management fees and improved brand perception.

4. Can consumers recycle pappedeckel at home?

Yes, provided they are free from food residue. In many cases, they can also be composted.

5. Which industries benefit most from pappedeckel?

Food and beverage businesses, including coffee shops, fast-food chains, and catering services, are leading adopters.

6. What is the future of pappedeckel in packaging?

With regulatory changes and rising consumer demand, pappedeckel is expected to capture a significant share of the global packaging market by 2030.